| Número de pieza | Tamaño nominal | Rango de Uso | Presión Máxima de Retroceso | Presión máxima de inflado | Peso del producto | Longitud Desinflada | Diámetro Desinflado | |

| LF001 | 1.5'' (30 mm) | 1.2'' - 1.75'' (30-44 mm) | 13 psi (0.9 bar) | 30 ft (9.1 m) | 40 psi (2.7 bar) | 0,07 kg de peso total | 4.25'' (108 mm) | 0,98'' (25 mm) |

| LF002 | 2'' (50 mm) | 1,9'' - 2,25'' (48-70 mm) | 13 psi (0.9 bar) | 30 ft (9.1 m) | 35 psi (2,7 bar) | 0.1KG | 2,84'' (72 mm) | 1,77'' (45 mm) |

| LF003 | 3'' (75 mm) | 2,77'' - 3,25'' (70-83 mm) | 13 psi (0.9 bar) | 30 ft (9.1 m) | 35 psi (2,4 bar) | 0.2kg | 5,25'' (132 mm) | 2,64'' (67 mm) |

| LF004 | 4'' (100mm) | 3,41'' - 4,25'' (87-108 mm) | 13 psi (0.9 bar) | 30 ft (9.1 m) | 30 psi (2,1 bar) | 0,3 kg | 6,5'' (163 mm) | 3,25'' (83 mm) |

| LF005 | 5'' (125 mm) | 4,6'' - 5,25'' (117-133 mm) | 13 psi (0.9 bar) | 30 ft (9.1 m) | 30 psi (2,1 bar) | 0.6kg | 7,25'' (200 mm) | 4,5'' (114 mm) |

| LF006 | 6'' (150 mm) | 5,44'' - 6,25'' (138-159 mm) | 13 psi (0.9 bar) | 30 ft (9.1 m) | 40 psi (2,8 bar) | 0.85kg | 9'' (230 mm) | 5,25'' (135 mm) |

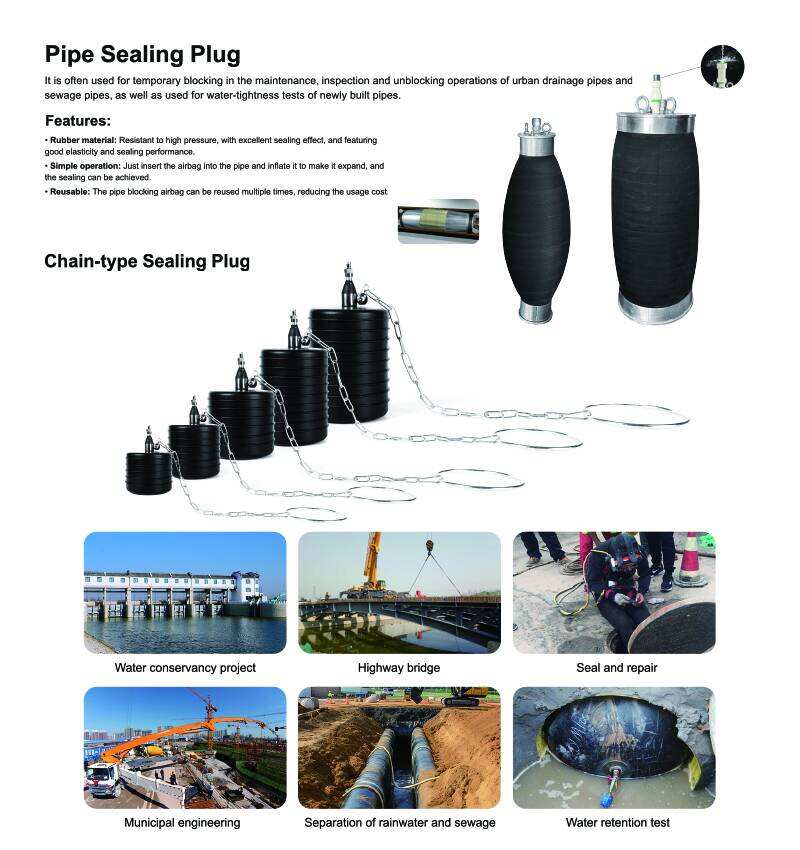

Nuestras tapas inflables para tuberías están diseñadas para ofrecer un sellado confiable y de alta presión para una amplia gama de operaciones de mantenimiento, pruebas y reparación de tuberías en múltiples industrias.

1. Gestión municipal y urbana de tuberías

● Mantenimiento de drenaje y alcantarillado: Proporciona aislamiento temporal de secciones de tubería durante la limpieza, inspección o reparación, evitando interferencias de flujo y permitiendo condiciones de trabajo seguras.

● Pruebas de presión y detección de fugas en tuberías nuevas: Se utiliza para pruebas de estanqueidad y presión en tuberías recién instaladas, garantizando el cumplimiento y la integridad del sistema antes de la puesta en marcha.

● Proyectos de Separación de Aguas Pluviales y Residuales: Permite la sección precisa de tuberías durante actualizaciones del sistema o proyectos de separación.

2. Proyectos Industriales e Infraestructura

● Conservación de Agua e Ingeniería Hidráulica: Bloqueo temporal para mantenimiento de canales, alcantarillas o tubos de desagüe en presas, embalses y sistemas de riego.

● Sistemas de Drenaje de Carreteras y Puentes: Aísla tuberías de drenaje bajo puentes o a lo largo de autopistas para inspección y reparación sin interrumpir el tráfico.

● Parada de Tuberías Industriales: Utilizado en drenajes de fábricas, líneas de efluentes químicos o tuberías de condensado de HVAC para mantenimiento seguro durante paradas programadas.

3. Respuesta a Emergencias y Rehabilitación

● Proyectos de Revestimiento para Rehabilitación de Tuberías: Sella tuberías durante el revestimiento de tubos curado en sitio (CIPP) u otros métodos de rehabilitación sin zanjas.

● Contención de Fugas de Emergencia: Despliegue rápido para contener temporalmente fugas o desbordamientos en tuberías dañadas antes de la reparación permanente.

Como fábrica especializada en soluciones de tuberías, garantizamos que cada tapón cumpla con rigurosos estándares de durabilidad, seguridad y facilidad de uso.

1. Diseño y Rendimiento Robustos

● Material de Caucho de Alta Resistencia: Fabricado con caucho reforzado resistente a la presión, con excelente elasticidad y recuperación, lo que asegura un sellado hermético incluso bajo condiciones de alta presión.

● Sistema de Bloqueo Seguro y Diseño Antideslizante: Superficie texturizada o correas integradas evitan el deslizamiento en tuberías lisas o inclinadas, manteniendo la posición durante las operaciones.

● Sistema de Inflado/Desinflado Rápido: Compatible con bombas de aire estándar para una implementación y recuperación rápidas, reduciendo tiempos de inactividad y esfuerzo laboral.

2. Fabricación y Garantía de Calidad

● Materiales de Grado Industrial: Resistentes a productos químicos de aguas residuales, exposición UV y abrasión, para una vida útil prolongada en entornos adversos.

● Proceso de Vulcanización de Precisión: Asegura un espesor uniforme, una fuerte integridad de costuras y un comportamiento consistente durante el inflado en todos los productos.

● Probado y Certificado por Presión: Cada tapón somete a pruebas de retención de presión y está clasificado para rangos claros de PSI de trabajo, con cumplimiento de estándares industriales donde sea aplicable

3. Eficiencia Operativa y Rentabilidad

● Reutilizable y Duradero: Diseñado para múltiples usos en diferentes proyectos, lo que reduce el costo por uso y el desperdicio en comparación con alternativas desechables.

● Rango Versátil de Tamaños: Disponible en múltiples diámetros y longitudes para adaptarse a tuberías desde pequeñas líneas de drenaje hasta grandes alcantarillas municipales.

● Fácil de Limpiar y Almacenar: Su superficie lisa permite una limpieza sencilla después del uso; se desinfla de forma compacta para un transporte y almacenamiento cómodo.

● Aislamiento de Tuberías de Múltiples Secciones: Ideal para sellar uniones, superficies irregulares o tuberías con obstrucciones donde los tapones estándar podrían no ajustarse de forma segura.

● Sellado de Cubierta de Puente y Juntas de Dilatación: Utilizado en proyectos de infraestructura donde se requiere sellado lineal o segmentado a lo largo de tramos de canal.

● Configuraciones Personalizadas: Pueden adaptarse en longitud y diseño de enlaces para necesidades técnicas especializadas.