| Αριθμός Άρθρου | Κανονισμός | Ελάχ. Διάμετρος Σωλήνα (mm) | Μέγ. Διάμετρος Σωλήνα (mm) | Μέγ. Πίεση Αντίθλιψης | Μέγ. Πίεση Φούσκωματος | Διάμετρος Προϊόντος (mm) |

| σφραγιστική Τσάντα 30mm | RPC-20-30S | 28 | 36 | 0,5bar / 7,5psi | 2 bar | 23 |

| σάκκος κλεισίματος 40mm | RPC-20-40S | 30 | 45 | 0,5bar / 7,5psi | 1,2bar | 30 |

| σάκκος κλεισίματος 45mm | RPC-20-50S | 45 | 54 | 0,5bar / 7,5psi | 1,2bar | 45 |

| σάκκος κλεισίματος 60mm | RPC-20-60S | 60 | 80 | 0,5bar / 7,5psi | 1,2bar | 59 |

| σάκκος κλεισίματος 70mm | RPC-20-75S | 70 | 85 | 0,5bar / 7,5psi | 1bar | 70 |

| σάκκος κλεισίματος 100mm | RPC-20-100S | 85 | 112 | 0,5bar / 7,5psi | 1bar | 83 |

| σάκκος κλεισίματος 110mm | RPC-20-110S | 100 | 125 | 0,5bar / 7,5psi | 1bar | 96 |

| σάκκος κλεισίματος 140mm | RPC-20-140S | 140 | 154 | 0,5bar / 7,5psi | 0,7bar | 131 |

| σάκκος κλεισίματος 150mm | RPC-20-150S | 150 | 180 | 0,5bar / 7,5psi | 0,7bar | 145 |

| τσαντα κολλώσεως 200mm | RPC-20-200S | 210 | 260 | 0,5bar / 7,5psi | 0,5 bar | 204 |

| τσαντα κολλώσεως 300mm | RPC-20-300S | 300 | 450 | 0,14bar / 2psi | 0,5 bar | 290 |

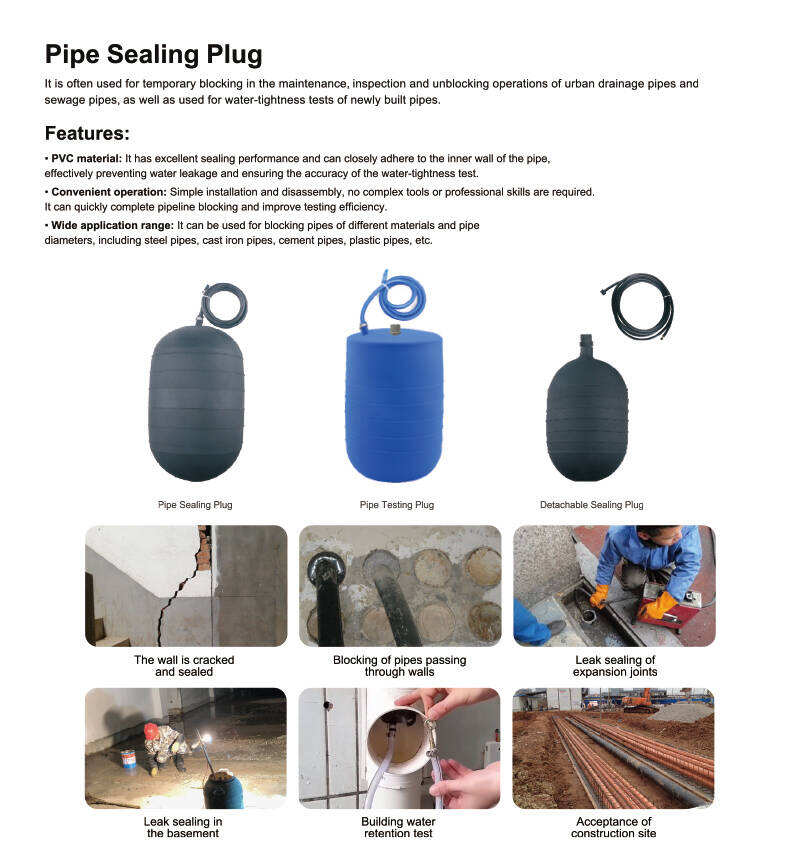

Τα φουσκωτά βύσματα σωλήνων μας είναι μηχανικά σχεδιασμένα για να παρέχουν αξιόπιστη σφράγιση υψηλής πίεσης για μια ευρεία ποικιλία εργασιών συντήρησης, δοκιμών και επισκευής αγωγών σε πολλούς τομείς.

1. Διαχείριση αστικών και αστικών αγωγών

● Συντήρηση αποχέτευσης και αποχετεύσεων: Παρέχει προσωρινό διαχωρισμό τμημάτων σωλήνων κατά τον καθαρισμό, την επιθεώρηση ή την επισκευή, αποτρέποντας τη διαταραχή της ροής και εξασφαλίζοντας ασφαλείς συνθήκες εργασίας.

● Δοκιμές πίεσης και διαρροής νέων σωλήνων: Χρησιμοποιείται για δοκιμές στεγανότητας με νερό και πίεσης σε νεοεγκατεστημένους αγωγούς, διασφαλίζοντας τη συμμόρφωση και την ακεραιότητα του συστήματος πριν από τη θέση σε λειτουργία.

● Έργα Διαχωρισμού Ομβρίων/Αποχέτευσης: Δυνατότητα ακριβούς τομής αγωγών κατά τη διάρκεια αναβαθμίσεων συστημάτων ή έργων διαχωρισμού.

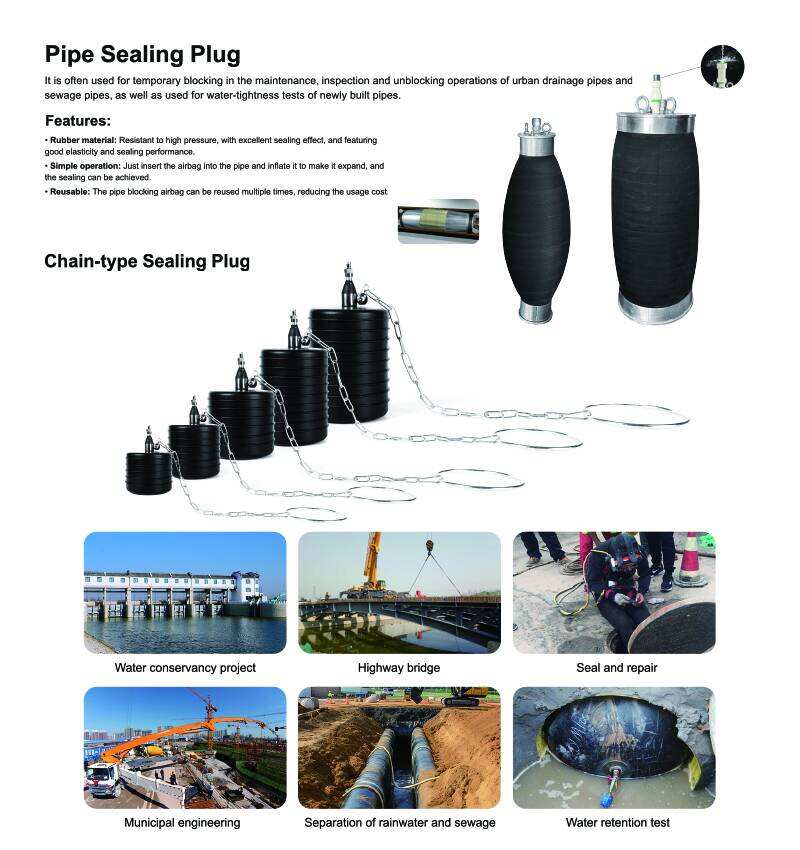

2. Βιομηχανικά & Υποδομικά Έργα

● Έργα Υδροληψίας & Υδραυλικής Μηχανικής: Προσωρινή φραγή για συντήρηση υδάτινων διαύλων, σηράγγων ή αποχετευτικών σωλήνων σε φράγματα, λίμνες αποθήκευσης και συστήματα άρδευσης.

● Συστήματα Αποστράγγισης Αυτοκινητοδρόμων & Γεφυρών: Απομόνωση αποχετευτικών αγωγών κάτω από γέφυρες ή παρά τους αυτοκινητοδρόμους για επιθεώρηση και επισκευή, χωρίς διαταραχή της κυκλοφορίας.

● Διακοπή Βιομηχανικών Αγωγών: Χρησιμοποιείται σε αποχετεύσεις εργοστασίων, αγωγούς χημικών αποβλήτων ή σωληνώσεις συμπυκνώσεως HVAC για ασφαλή συντήρηση κατά τη διάρκεια αδρανοποίησης.

3. Επείγουσα Ανταπόκριση & Αποκατάσταση

● Έργα Επένδυσης Αποκατάστασης Αγωγών: Σφραγίζει αγωγούς κατά τη διάρκεια επένδυσης σωλήνων με τη μέθοδο cured-in-place pipe (CIPP) ή άλλες τεχνικές ανεξάρτητες από σκάψιμο.

● Περιορισμός Επειγόντων Διαρροών: Γρήγορη εγκατάσταση για προσωρινό περιορισμό διαρροών ή υπερχειλίσεων σε βλαβείς αγωγούς πριν από τη μόνιμη επισκευή.

Ως εργοστάσιο ειδικευμένο σε λύσεις σωληνώσεων, διασφαλίζουμε ότι κάθε βύσμα πληροί αυστηρά πρότυπα ανθεκτικότητας, ασφάλειας και ευκολίας χρήσης.

1. Ισχυρός Σχεδιασμός & Απόδοση

● Υλικό Υψηλής Αντοχής Λάστιχου: Κατασκευασμένο από ενισχυμένο, ανθεκτικό στην πίεση λάστιχο με εξαιρετική ελαστικότητα και ανάκαμψη, εξασφαλίζοντας στεγανότητα ακόμη και σε συνθήκες υψηλής πίεσης.

● Ασφαλής Κλειδώνων & Αντιολισθητικός Σχεδιασμός: Διακοσμητική επιφάνεια ή ενσωματωμένες ταινίες που αποτρέπουν την ολίσθηση σε λείες ή κεκλιμένες σωληνώσεις, διατηρώντας τη θέση κατά τη διάρκεια των εργασιών.

● Σύστημα Γρήγορης Πλήρωσης/Αποκλείσεως Αέρα: Συμβατό με τυποποιημένες αντλίες αέρα για γρήγορη εγκατάσταση και απομάκρυνση, μειώνοντας το χρόνο αδράνειας και την εργασία.

2. Παραγωγή & Εξασφάλιση Ποιότητας

● Βιομηχανικού Βαθμού Υλικά: Ανθεκτικά σε χημικά απόβλητα, έκθεση σε υπεριώδη ακτινοβολία και φθορά, για μεγαλύτερη διάρκεια ζωής σε δύσκολα περιβάλλοντα.

● Ακριβής Διαδικασία Θειώσεως: Εξασφαλίζει ομοιόμορφο πάχος, ισχυρή ακεραιότητα ραφών και σταθερή συμπεριφορά πλήρωσης σε όλα τα προϊόντα.

● Δοκιμασμένος και πιστοποιημένος ως προς την πίεση: Κάθε βύσμα υποβάλλεται σε δοκιμασίες συγκράτησης πίεσης και έχει βαθμονομημένο εύρος λειτουργικής PSI, με συμμόρφωση προς τις βιομηχανικές προδιαγραφές όπου εφαρμόσιμες

3. Λειτουργική Απόδοση και Οικονομική Αποτελεσματικότητα

● Επαναχρησιμοποιούμενος και μεγάλης διάρκειας: Σχεδιασμένος για πολλαπλές εφαρμογές σε διαφορετικά έργα, μειώνοντας το κόστος ανά χρήση και τα απόβλητα σε σύγκριση με μία χρήση εναλλακτικές.

● Ποικιλία διαστάσεων: Διαθέσιμος σε πολλαπλά διαμετρήματα και μήκη για να ταιριάζει σε σωλήνωσεις από μικρές στραγγενευσεις μέχρι μεγάλους αστικούς σωληνωτούς φρεατίους.

● Εύκολος καθαρισμός και αποθήκευση: Η λεία επιφάνεια επιτρέπει εύκολο καθαρισμό μετά τη χρήση· συρρικνώνεται συμπαγώς για άνετη μεταφορά και αποθήκευση.

● Απομόνωση Πολυτμηματικών Σωληνώσεων: Ιδανικός για σφράγιση διαμέσου αρμών, ανώμαλων επιφανειών ή σωλήνων με εμπόδια όπου τα τυπικά βύσματα δεν ταιριάζουν με ασφάλεια.

● Σφράγιση Γέφυρας & Αρμών Διαστολής: Χρησιμοποιείται σε έργα υποδομής όπου απαιτείται γραμμική ή τμηματική σφράγιση κατά μήκος των ανοιγμάτων.

● Προσαρμοσμένες Διαμορφώσεις: Δύναται να προσαρμοστεί ως προς το μήκος και το σχεδιασμό σύνδεσης για εξειδικευμένες μηχανικές ανάγκες.